Enterprises that manufacture 3D printing equipment serve as the starting point for this study, and they are analyzed using the PEST analysis, the five forces model, and the SWOT model. They are thoroughly examined at both the macro and micro levels in order to provide relevant development suggestions for 3D printing midstream enterprises, respectively.

The first point to mention is the political climate.

The rapid development of the 3D printing industry has resulted in the main bearer of the 3D printing industry, 3D printers, entering a golden age in terms of research and development, as well as sales and marketing. 3D printers are the most important bearer of the 3D printing industry. The quality and advancement of 3D printer technology will have a direct impact on the development of the 3D printing industry in my country, and this will be especially true in the future. A number of policies have been issued by the Chinese government in recent years to encourage the development of 3D printer manufacturing enterprises, as well as an equal number of policies to encourage the advancement of printer skills, as a result.

2. The Economic and Business Environment

With the rise of my country's economic level comes the creation of a favorable environment for midstream businesses in the 3D manufacturing industry. Because of the rapid acceleration of my country's industrial transformation and upgrading, there is a rapid expansion of the market demand for 3D printing products in the short term, at least in the short term. As the costs of land, labor, and other inputs have risen at an alarming rate in recent years, the need for industrial transformation and upgrading in my country has become increasingly urgent. As a result of this development, the pace of industrial transformation and upgrading in my country will be accelerated even further. Chinese companies will reduce the amount of time it takes for new products to reach the market and will improve the quality of their products at the same time. Every day, the demand for design capabilities grows stronger and stronger, and the 3D printer manufacturing industry is perfectly positioned to meet the demands of the industrial transformation that is currently underway.

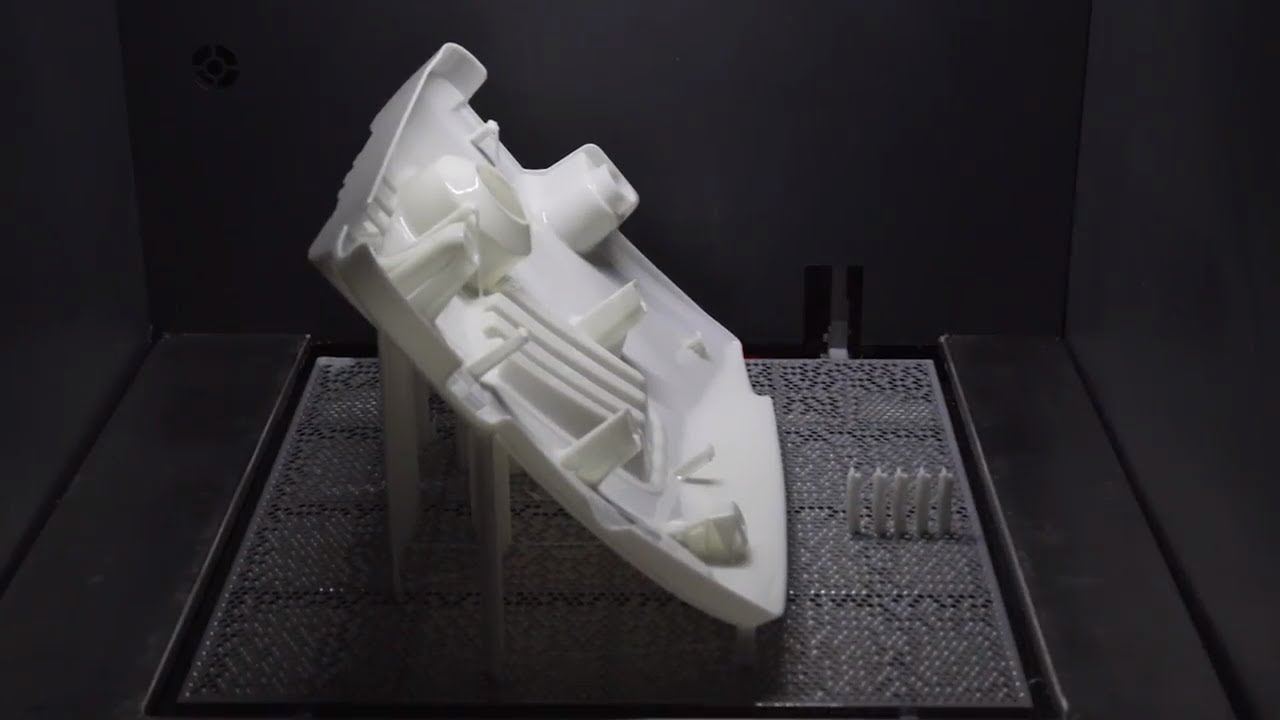

This will lead to an increase in demand for 3D printing equipment used for product design and prototype development in the future, as well as a favorable economic environment conducive to the development of 3D midstream enterprises in the near future. A further consequence of the rapid development of the aerospace, national defense, and military industries has been an increase in the demand for 3D printing equipment on an as-needed basis, particularly in the aerospace and national defense sectors. My country is currently undergoing a period of rapid development in the aerospace, national defense, and military sectors, among other areas. Implementing the National Strategic Emerging Industries Program's inclusion of aviation equipment, satellites, and applications will provide critical support.3D printing techniques that use precision lasers to create complex shapes, such as near-net-shape printing, have a lot of potential in the manufacturing of aircraft and satellite parts that are difficult to fabricate and process.

3. The social and cultural context of the situation

With regard to today's socioeconomic environment, the majority of current 3D printer companies have grown as a result of the increase in the number of index corporate users, which is a positive development. Historically, the success of 3D printer manufacturers' products has been closely tied to the success of their enterprise customers.

In contrast, a large number of ordinary people became interested in 3D Printing Services right from the start of the process. In addition to showing that a growing number of people are becoming aware of 3D printing and have formed their own preliminary judgments about its functions and principles, this level of interest also demonstrates that a growing number of people are attempting to learn more about 3D printing. Three-dimensional printing (3D printing) is a mystery, and people are eager to witness its magical effects, learn about how it works (such as how it works), and experience the transformations brought about by 3D printing from the virtual to the real world (and vice versa). With respect to this specific case, an increasing number of 3D printer manufacturers initially concentrated their attention on the market for small home printers and developed a development route for producing and developing personalized small printers on a small scale.

4. The Environment for Skill Development

This is due to the fact that 3D printing is a revolutionary industry, and the fact that research and development in 3D printing technology is extremely abundant all over the world, resulting in a strong technical foundation for 3D printer manufacturing. The innovation-driven development strategy in my country, on the other hand, is seen as a national strategy for modernizing development methods and speeding up industrial transformation and upgrading. As a result, my country has steadily increased its efforts in the areas of technological innovation, industrial applications research and development, and research and development of new products. Given the fact that 3D printing is a young industry, there are numerous opportunities for technological advancement and development.

Manufacturing restrictions on 3D printing parts are becoming increasingly lax in recent years, as evidenced by the wide variety of materials available for use in 3D printers. The materials that cannot be printed, despite the fact that high-end industrial printing is capable of printing on materials such as plastic, certain metals, and ceramics, are relatively expensive and difficult to come by. Researchers are experimenting with the construction of 3D printers from materials that are becoming increasingly inexpensive and readily available, and they have made significant advances in the field of multi-material printing in the process. As a side note, printers are becoming increasingly compact and lightweight as their size and quality improve. As 3D printer technology has progressed in recent years, manufacturers have been able to produce one or even several small printers in a single day, allowing them to not only meet market demand but also reduce production time.